how tea is made

Tea is made 3 times; once in the farm, then in the factory, and then in your kitchen. We know all about the kitchen part but less about the other parts, which you can learn about here.

First of all, some basics.

Tea Type

SPILL tea is a black tea. It comes from the tea bush; camelia sinensis. Green tea also comes from camelia sinensis, the very same plant; it’s just processed in a different way.

Herbal tea doesn’t; it shouldn’t be called tea, really, but it’s easier than saying “infusion”. All tea is grown between the tropics; needs sun and rain.

SPILL tea comes from Rwanda. It's volcanic soil, tropical sun and big showers are the things that make great tasting tea.

origin

Rwanda

Elevation

High - 2000m-2700m

Process

Oxidised Black Tea

Taste, appearance

Bold. Full Bodied. Thick. Golden.

origin

Rwandan tea is a tea taster's secret. Rwanda grows just 1% of the worlds tea, we think its the best 1%

Elevation

Rwanda is known as the land of a thousand hills. The higher the elevation, the slower the tea grows and the deeper the flavour of the tea.

Process

This is a black tea so once the teas are plucked and dried, they are left to ferment or oxidise - this means the air gets to the leaves and turns them black. The oxidation is what gives black tea it's deep flavour and colour perfect with milk.

Taste, appearance

This tea really hits the spot and tastes exactly how you want an everyday tea to taste.

Tea Processing

All tea is turned from fresh green leaves to dried leaf you can actually drink in the country where it's grown. There are quite a few steps. And they are completed in 24 hours. Fast!

The photo above is the factory team at Rugabano where SPILL is made. Each person is allocated to work on one of the tea processing steps. And wears the uniform to go with it. They've lined up in the order it all happens in for us.

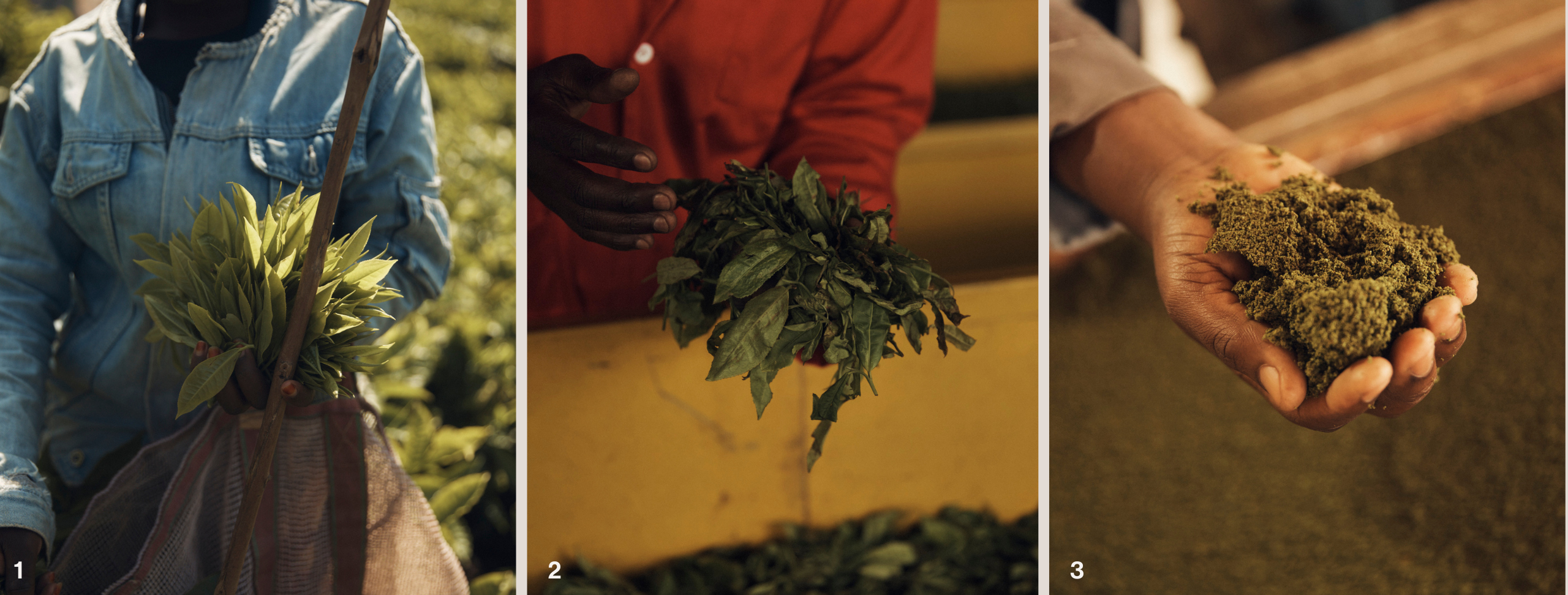

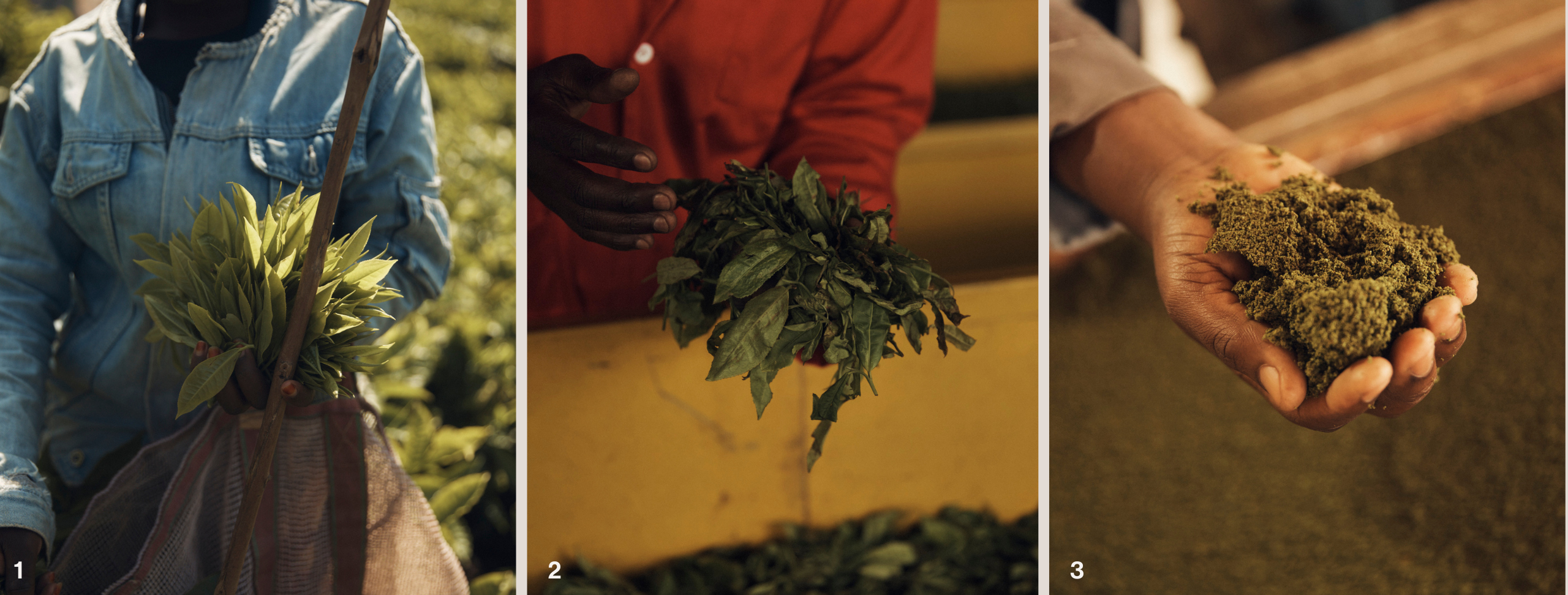

1. PLUCKING

There’s good plucking and bad plucking. What makes a good leaf? 2 leaves and a bud from the top of the tea bush. Small and juicy. Not big and tough. In Rwanda, this is a formal plucking standard and farmers receive a premium for leaves that meet this standard. And they pluck by hand.

2. WITHERING

The leaves are left to shrivel. Or wither, which is a nicer word. This reduces the moisture content of the leaf. We know the leaf is ready when it can be squeezed and doesn't pop back - technical, we know. Rugabano factory manager, Anjum, tells us 90% of how the tea will turn out is determined by this stage. If the leaf isn't good to begin with and the water content isn't right, there's only so much you can do to influence the flavour. And there's no going back.

3. CUTTING

We use the CTC method. This stands for Cut Tear Curl. Which is what happens to the leaf to turn it into smaller pieces. Cutting the leaf releases the flavour.

4. FERMENTATION

This is the stage where the freshly cut leaf turns from green to brown because the air is getting to the juicy centre of the leaf. It also starts to smell of Bananas - nice and sweet

5. DRYING and SORTING

The tea is dried to take out the moisture content from the tea and seal in the flavour. The outside of the leaf is now dark brown. The tea is then sorted - it goes through different sieves separating leaf sizes, the bigger leaf goes into our loose tea and a smaller leaf goes into our tea bags.

6. PACKING

The finished tea, now in different leafs sizes, is packed into very very big sacks of 60kgs+. The batch numbers, production date are stencilled on and they are ready to go on the road.

Good Tea. Nothing To Hide.

We paid $3 / kilo - 50% above Fairtrade - Plus, additional farmer payment $0.50 / kilo.